Call us now

07971891562195

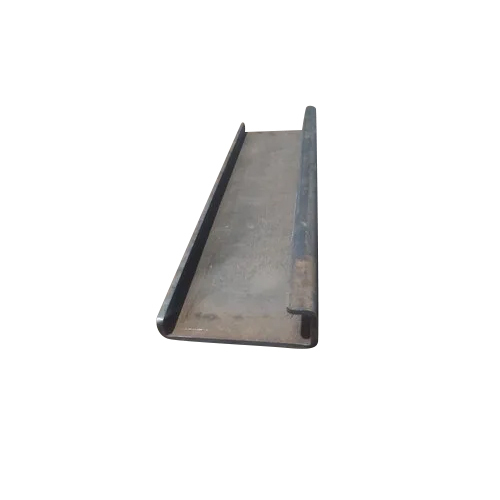

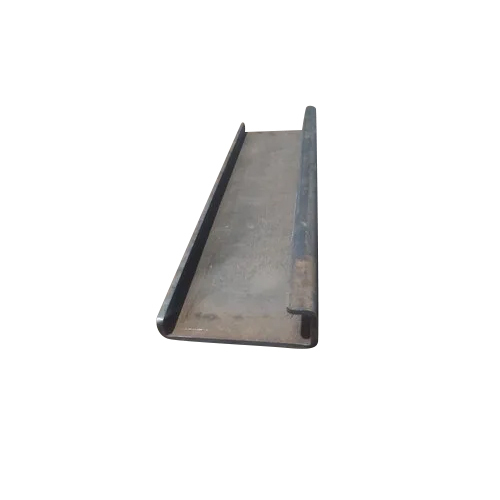

About Gi Sheet Bending Services Detail

Unlock world-class precision with our GI Sheet Bending Services, now at an unbeatable price! Take advantage of a major markdown-this is your last chance to transform GI sheets up to 1250 mm wide and 4000 mm long with a polished finish and lofty standards. Utilizing advanced Hydraulic Press Brake technology, we maintain a tight tolerance of 0.5 mm. Our zinc-coated surfaces promise superior corrosion resistance. We serve both on-site and at our service center, offering full customization for HVAC, ducting, cable trays, and structural projects across India. Distributors, manufacturers, service providers, suppliers, and traders: don't miss out!

Surface Versatility and Broader Applications in GI Sheet Bending

Our GI Sheet Bending Services deliver a polished surface finish through zinc coating, optimally suited for demanding industrial environments. Common applications include HVAC systems, ductwork, cable trays, structural components, and more, ensuring versatile usage. Employing advanced hydraulic press brake methods, we achieve precise bends for varied surfaces, adapting to custom specifications to meet unique project demands. From industrial plants to construction sites, our bending solutions maximize surface utility and efficiency for every end-use scenario.

Fast Delivery & Reliable Logistics for GI Sheet Bending Services

Experience quick dispatch on all GI Sheet Bending Services with efficient handling at every step. We ship directly from major FOB ports in India, ensuring prompt and seamless deliveries nationwide. Each order is carefully packaged to guarantee safe transit and minimize freight charges, no matter the order size. Our responsive team coordinates logistics with care, providing reliable service whether the end location is your site or our service center, enabling tight project timelines and reduced overhead costs.

Surface Versatility and Broader Applications in GI Sheet Bending

Our GI Sheet Bending Services deliver a polished surface finish through zinc coating, optimally suited for demanding industrial environments. Common applications include HVAC systems, ductwork, cable trays, structural components, and more, ensuring versatile usage. Employing advanced hydraulic press brake methods, we achieve precise bends for varied surfaces, adapting to custom specifications to meet unique project demands. From industrial plants to construction sites, our bending solutions maximize surface utility and efficiency for every end-use scenario.

Fast Delivery & Reliable Logistics for GI Sheet Bending Services

Experience quick dispatch on all GI Sheet Bending Services with efficient handling at every step. We ship directly from major FOB ports in India, ensuring prompt and seamless deliveries nationwide. Each order is carefully packaged to guarantee safe transit and minimize freight charges, no matter the order size. Our responsive team coordinates logistics with care, providing reliable service whether the end location is your site or our service center, enabling tight project timelines and reduced overhead costs.

Our Products

Our Products